Snipe

Dynamic Inspection for Induction Sealing

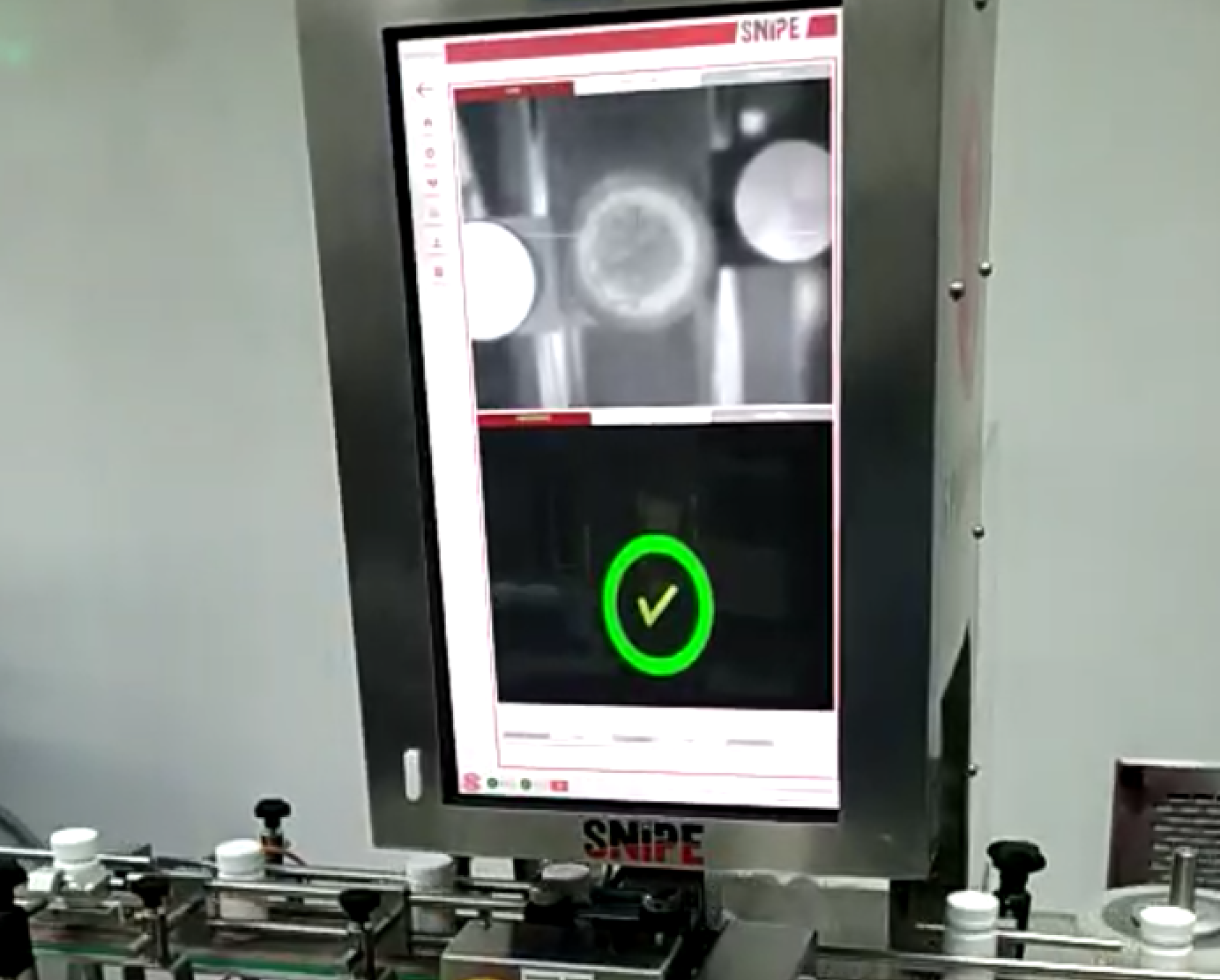

Snipe is an instrument that can detect most of the sealing errors in induction sealing. Without stopping production. Without opening a single cap. Snipe can run at low or high line speeds and is used to identify bad sealed bottles and eject them out of your production line.

¿How does it work?

We use Military Grade Infrared Thermal cameras and we analyze the images in real time with Artificial Intelligence and Machine Learning to detect the bottles with a sealing error and eject them so they never leave your factory.

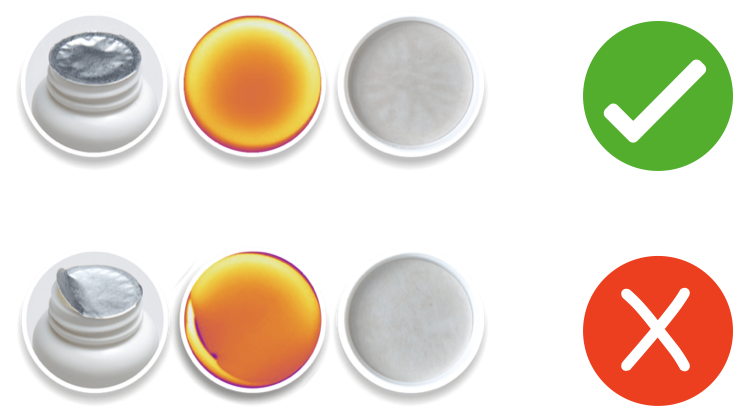

The seal is checked in every single container without stopping the line or reducing your production speed, or even taking a single cap off. We analyze the heat pattern on the outside of the cap. This heat signature is different depending on what has happened with the induction seal inside.

Snipe will identify each error type and keep record with stats so that you know what has happened, but that will also help you avoid them in the future.

Error types detected

Snipe can identify most sealing errors.

Each sealing error produces changes in the normal temperature pattern. These changes can be detected.

Foil related errors (folded, broken, off center, double, inverted, missing, etc)

Cap related errors (cocked, irregular torque, uneven pressure, broken, etc)

Container related errors (bad contact, irregular surface, contaminated area, etc)

Sealer related errors (wrong setting, low or high temperature, alignment, coil type, etc)

Custom errors “Taylor made” (teaching Snipe a new type of error that is unique to your packaging or your product is simple and fast thanks to the advanced integration of state-of-the-art machine learning)

Costs and waste due to leaks can be avoided. Returns of unsealed bottles. Loss of your product smell or crisp. Brand image. Bad seals can be detected with Snipe.

We check the good seal on every bottle.

With IR thermal cameras.

With Artificial Intelligence and Machine Learning.

100% of your production is inspected, every single bottle.

0% reduction output of your production speed.

Without opening any caps.

Without stopping any bottles.

We can implement Snipe in about 8 weeks time on your line.

Contact us for more information.

At quatropack, we are induction sealing specialists.

Efficient solutions that improve your product and sets it apart from the rest.